| |

While most new users will get tremendous benefit with some basic racing data system sensors

below are some of our most popular Racing Data Acquisition Sensor options.

|

|

"NEW" Low Air Pressure and Vacuum Sensor. The Perfect Sensor For Measuring Air Box Pressure for testing Aero Dynamics to Cooling System and Cooling and Brake Duct Air Pressures Our New Low Pressure and Vacuum Sensor is the perfect sensor to measure air pressures (or vaccuum) at any point of the racecar. Do you know if your NACA duct is in a high pressure area of the car? Do you know if your cold air intake (or air box) is really getting high pressure cold air to your engine's manifold? Is the air intake to your brake cooling ducts in the best spot? This sensor is used for PRACTICAL aerodynamic testing at the race track. This low pressure air sensor can measure both pressure and vacuum (for showing negative pressure areas), at many parts of the race car. The sensor can be placed right inside an air or cooling ducts, or a hose can be fitted over the nipple to allow remote sensing in areas where the sensor does not fit easily. The aero sensor outputs a voltage based on pressure changes which is then analyzed using our data acquisition software. $199 |

|

|

Steering Position Sensor, Steering Angle Sensor

The steering sensor is a simple but very effective way to determine the handling of a race car. Make a change and see if the change requires more (push) or less (loose) steering wheel movement through EVERY corner. Steering Sensors can be used to see if steering wheel movement CAUSED a handling problem. Also helps to increase the feedback between the crew and the driver. It is installed next to the steering shaft so an o-ring drive belt can rotate the sensor as the driver turns the wheel. The steering sensor outputs a voltage based on steering angle which is then analyzed using our data acquisition software. $119

|

|

|

Throttle Position, Throttle Angle Sensor (TPS) Used for measuring how far the throttle is open and for how long. Fast times are usually generated form the amount of time at or near maximum throttle opening. The sensor can be used to evaluate problems with the race vehicle as well as being used for driver analysis. $119 lever type pictured at far left; Rotary position (throttle shaft mount) also shown. For difficult mounting applications a string type throttle sensor is available.

|

|

|

Throttle or Gas Pedal Plunger Position Sensor, Throttle Angle Sensor

This Throttle position sensor is called a plunger or linear throttle position sensor. The throttle sensor can be operated by the race car's throttle cable or racecar throttle lever pushing in on its plunger. The plunger itself is spring loaded in the extended position. Total travel of this throttle position sensor is 1.5". In the photo to the left, the sensor is installed in a Porsche race car, and is operated by the throttle cable. This sensor can also be used to measure as a brake pedal travel sensor, or other applications that require position. $109 |

|

String (Cable) Type Position

Sensor (applications include Throttle, Steering, and Universal Position

Sensing)

In

applications where conventional sensors can be difficult to install, the

String Type position sensor makes mounting a snap. A small string (wire) is

connected to a spring-loaded sensor inside the black housing. Attach the

string to an object that moves and the sensor will take care of the rest.

For example it may be difficult to connect to the throttle linkage directly,

but using a string allows the sensor to be mounted remotely and let the

linkage pull the string (because of its ease of installation this is our

most popular sensor for Throttle Position). It can also be used to wrap

around rotating object like a twist throttle, or to wrap around a steering

shaft to monitor steering position, or for many other components that

require position sensing. (note: this sensor is not recommended for

suspension travel)

Sensor is available in 2.75 (most common for throttle), 4.75” or 10” of travel. $219

|

|

|

|

Rotary Position Sensor, can be used as a Shock or SuspensionTravel Sensor, (bell crank shock applications) Throttle Position Sensor, or any device that requires a precision rotational measurement on the race car.

This sensor is a precision potentiometer that allows precise measurement of any rotary types sensor on the race car. This sensor can be custom order to read in 10 degree increments of rotation. This is very important when using this sensor as a shock or suspension travel sensor particularly when measuring shock velocities. It has a slotted end that allows for easy installation of any flat piece of metal to rotate the sensor. $259 |

|

EGT

(Exhaust Gas Temperature) and/or

CHT (Cylinder Head Temperature)

These Racing Exhaust Gas Temperature sensors are available for those who require to know specific EGT temperatures at ANY portion of the racetrack. Data graphs are plotted throughout the racetrack to let you see exactly what your engine is doing at any given point. Exhuaust Gas Temperature EGT sensor have exposed tips (not sealed tips) to give the fastest EGT reaction times to measure fuel mixture changes FAST.

Note: Our temperature probes are designed specifically for high pressure racing appplications and should not be confused with "standard" EGT probes

$75 EGT or Cylinder Head Sensor with 2' Stainless Steel Lead.

|

|

|

Water Temperature, Oil Temperature or other Fluid Temperature

These Racing SEALED Racing K Type Temperature sensors are available for those who require to know specific critical engine temperatures at ANY portion of the racetrack. Water temperature, oil temperature, trans transmission temperature, rear end temperature are just a few of the racing temperatures these sensors can record.

These temperature sensors have a 3/16" probe which is SEALED to allow them to be submerged into a liquid.

Note: Our temperature probes are designed specifically for high pressure racing appplications and should not be confused with "standard" temp probes

$75 SEALED liquid racing temperature sensor with 2' Stainless Steel Lead.

|

|

|

|

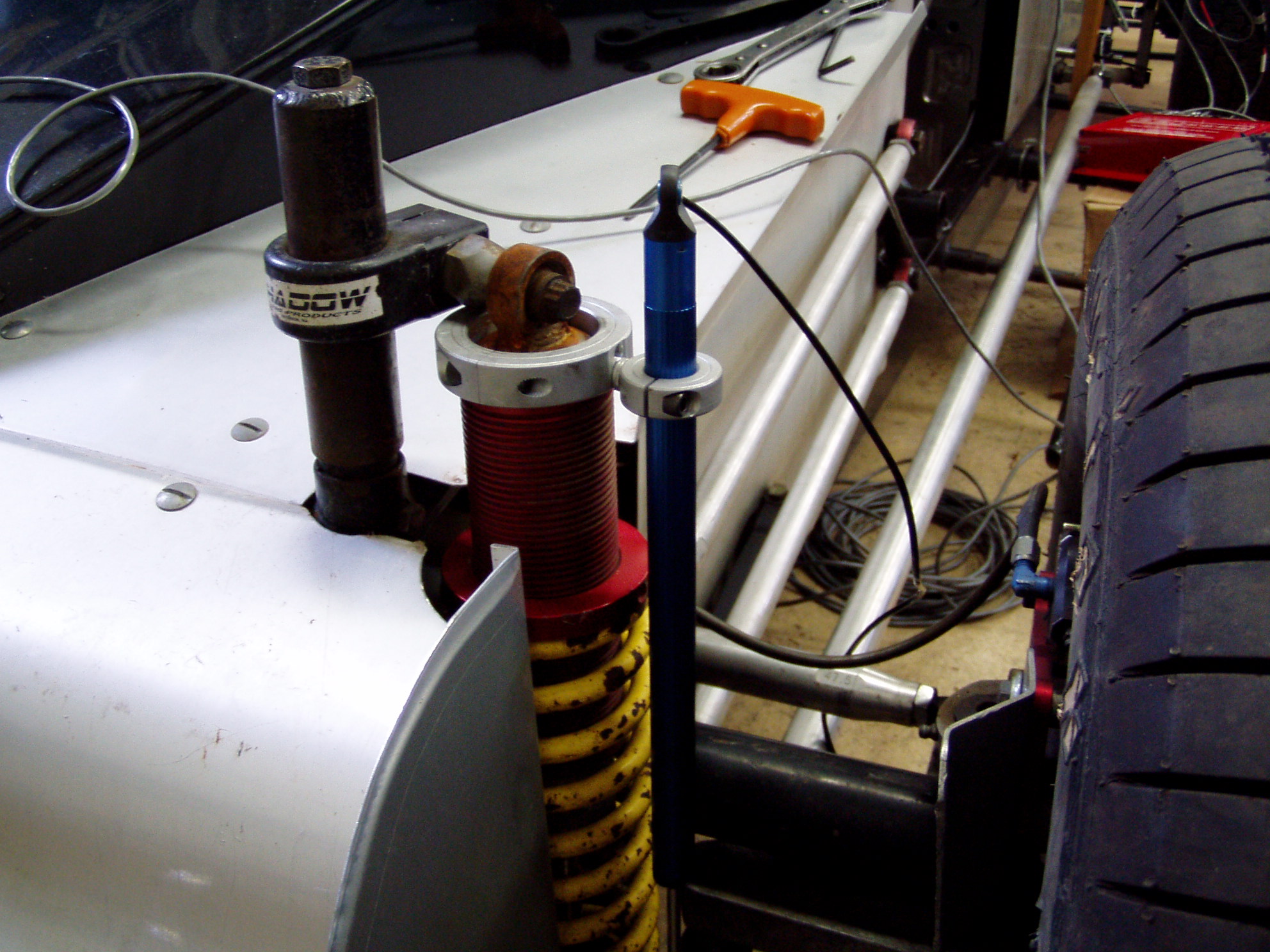

Suspension

Travel Sensor This

device allows for the suspension travel to be monitored by the data

acquisition system. The sensor outputs a voltage based on

suspension position which is then analyzed using our data acquisition

software. Constructed of high quality components the sensor

features spherical rod ends at each end for mounting, and have an

anodized metal body. Cost varies with travel range required.

Typical cost $250 each.

|

|

“G” Force Accelerometer:

The perfect companion for our Professional Data Group system, this sensor

allows you to measure “G” force at any point of the track. The sensor is

available in either single axis or dual axis. Single axis can be used for

cornering (lateral “G” force) OR braking (longitudinal “G” force) depending

on how you position the sensor. Dual Axis Sensors allow you to measure both

at the same time. Dimensions for either sensor is 4” X 2.75” X 1”.

Single Axis “G” Sensor $199 Dual Axis “G” Sensor $249.

(note: Our Ultimate 30 Data System has built-in 2 Axis accelerometer“G” sensors)

(Our new Leading Edge Data system has a built in 1 Axis acceleromter G Sensor)

|

|

|

|

MINI “G” Force Accelerometer:

Designed for extremely tight or specialty remote “G” sensing applications,

this “TRICK” sensor is measures only 1” X 1” x .75” and can be mounted with

rivets or velcro. Available as either Single Axis or TRI (3) X,Y & Z Axis

(Lateral, Longitudinal, and Up and Down), these 0-4 “G” sensors include the

internal electronics/filtering to give very accurate data.

Single Axis “G” Sensor $253 TRI (3) Axis “G” Sensor $424. |

|

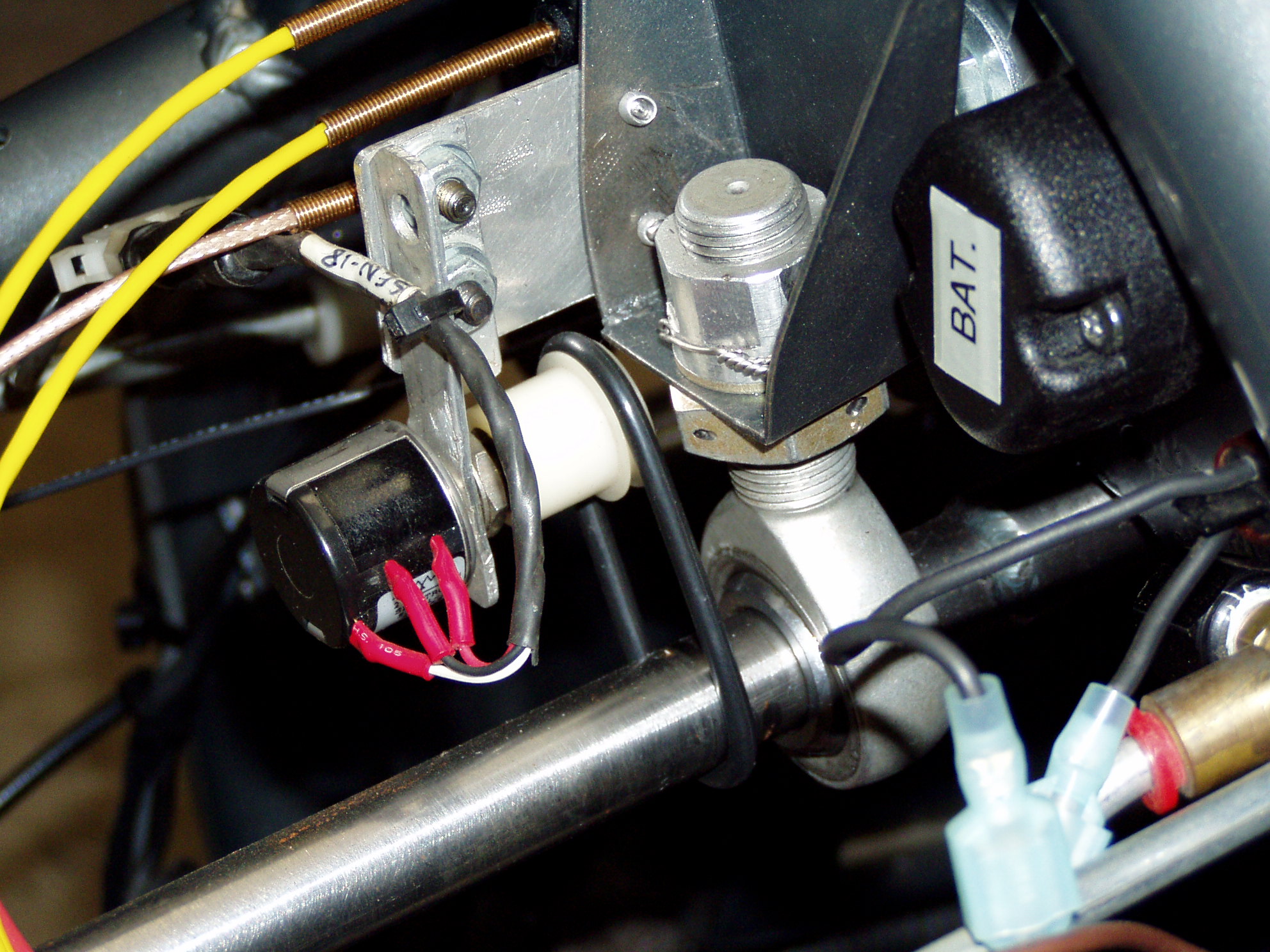

PRESSURE

SENSOR:

Used for measuring pressure, these sensors are commonly used for engine

analysis. Oil, Water, Fuel, Boost, Brake, Nitrous pressure,

and more can be measured with these sensors. These sensors

are very high quality, featuring stainless steel construction, and our

very durable in a high vibration environment. (note: cheaper sensors

will not last in a high vibration environments). 1/4 NPT threads

allow the sensor to be threaded into standard fittings. $215

Many ranges are available from 0-2500 P.S.I. the most common applications 100 psi pressure sensor, 250 psi pressure sensor, 1000 PSI pressure sensor (normally used for Brake Pressure) sensor typically 1000 PSI

|

|

|

AXLE,

WHEEL, or DRIVE SHAFT Sensor

This sensor is used for measuring

MPH as well as RPM of axle shafts, drive shaft, and input shafts.

This sensor is the one of the most important sensors that you can

monitor, which is why it comes standard with our "Results" and

"Professional" Data systems. The sensor works by

sending a signal to the data logger when the magnet(s) passed by.

The software will

calculate MPH, speed through the corners, clutch slip and more with this

sensor. $60

additional special HI-GAUSS magnet $15. (magnets are housed in a

1/4 Allen screw) |

|

|

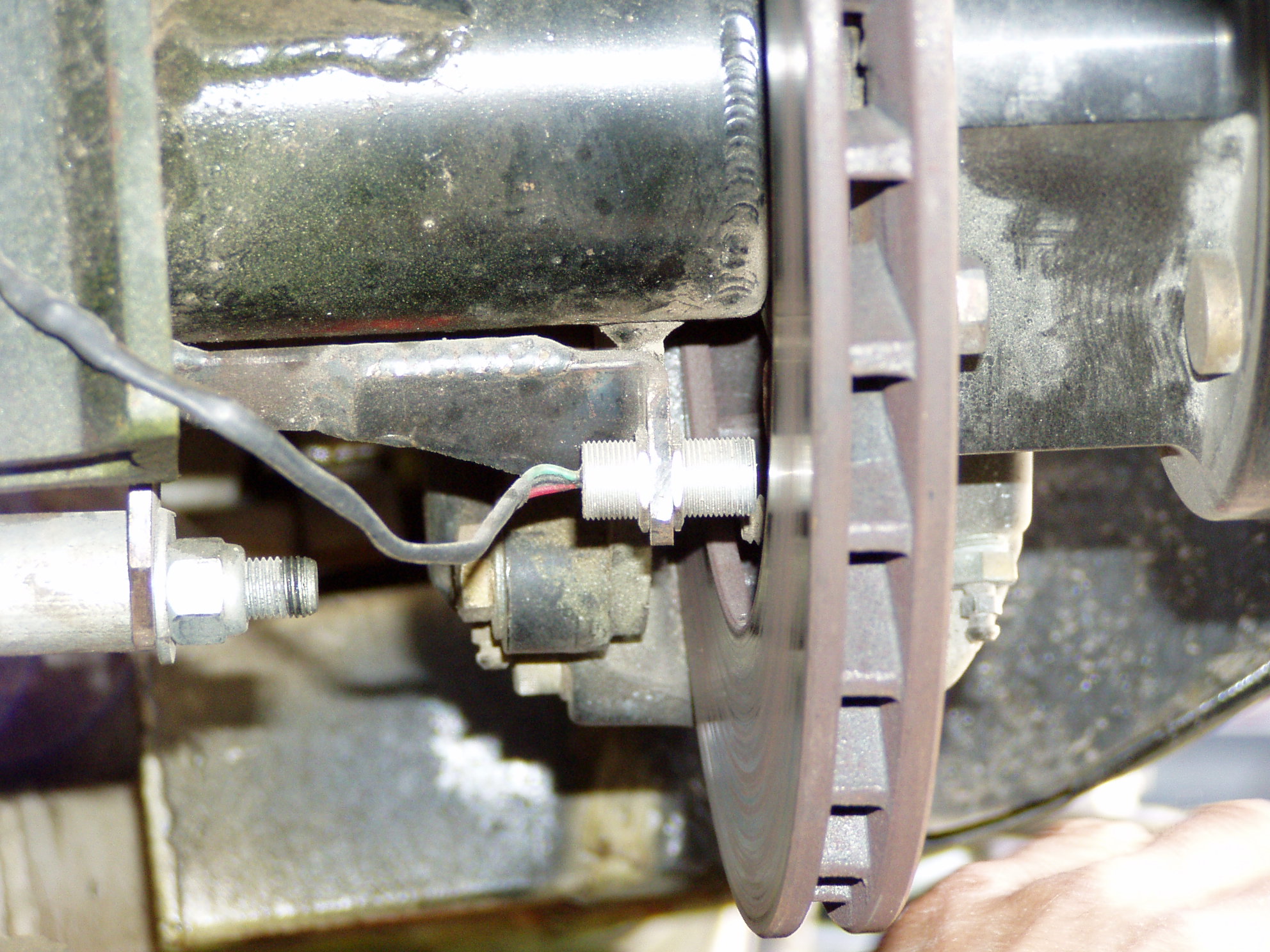

AXLE, WHEEL, or BRAKE ROTOR Sensor

This sensor is used for measuring MPH and DOES NOT require an external magnet to measure wheel speed. (Wheel speed (MPH) is important for track mapping, braking distances, speed through the corners etc. This sensor can pickup up a signal from any metal bolt. The most common installation for the Speed sensor is to point the sensor at the bolt(s) that hold the Brake Rotor or Wheel Hub on. If you have a stock car, this is the most popluar installation on wide five, or 5 on 5 wheels. An alternative method on some racecars is to attach a bolt to the rotating hub and have it pass by the sensor. The software will calculate MPH, speed through the corners, distance around the race track and more with this sensor. $75

|

While most of our system are designed to go directly the to the data logger,

we also sell gauge systems that can also be viewed without the data logger

|

Wide Band Air Fuel Ratio Sensor with UEGO Controller: One of our most popular selling sensors this year, analyzing exact Air Fuel Wide Band at any point of the racetrack is what this sensor does. A precise way to measure Air/Fuel Ratio. This 02 UEGO sensor is designed to output a voltage when measuring from 8:1 to 19:1 Air/Fuel Ratio. Works with Unleaded Gasoline, Nitrous, or Alcohol. As with all 02 sensors, this sensor will also work with Leaded Gasoline (or lead additives) for short periods of time, but it is recommended that it be removed and cleaned after tuning temperatures.

Available in either single wide band or dual wide band (2 sensors) applications, These Air Fuel Ratio Sensors come complete with all the necessary hardware and harnesses needed. The silver module pictured to the left controls the sensor current.

Accurate to 0.1 AFR

Available in Single or Dual 02 Sensor Modes

Bosch Wide Band 02 Sensors Included

0-5 Volt Calibrated Output (with 0-1 Volt secondary output available)

Unlike many other wide band 02 sensors Operates at

with battery voltages as low as 9 Volts

Complete single wide band kit $399 --- Complete Dual 2 Sensor Kit $599

Replacement Sensors can be purchased seperately ($100) Weld-In Bung $15.

|

|

Air Fuel Ratio O2 Sensor:

A precise way to measure Air/Fuel Ratio. This sensor is designed to output

a voltage when measuring from 12:1 to 16:1 Air/Fuel Ratios. Works with

Unleaded Gasoline, Nitrous, or Alcohol. As with all 02 sensors, this sensor

will also work with Leaded Gasoline (or lead additives) for short periods of

time, but it is recommended that it be removed and cleaned after tuning.

This sensor should be installed into the exhaust system near the exhaust

header, as the sensor must be 600°F to operate. The sensor also has and internal 12V heater to insure accurate readings at low exhaust temperatures. Air Fuel Ratio Sensor with Heater $99 / Weld-In Bung $15.

|

|

|

Turbo Boost Sensor: This sensor allows for measurement of Turbo Boost Pressure as well as engine vacuum for precise monitoring of engine load and boost requirements. The sensor automatically adjusts for atmospheric conditions and outputs a signal voltage in the positive or negative directions based on whether it senses engine vacuum, or manifold pressure (Boost). $119

(Note:

For Supercharger applications use our “Pressure Sensor”) |

We carry a complete line of

sensors, if you don’t see it, we can get it! The sensors below are an example

of some of our more elaborate sensors used for engineering.

|

RADAR Speed/MPH Sensor:

Designed for engineering

applications, this sensor measures relative motion. Point the sensor at

what you want to measure and speed will be measured. Either the sensor or

the target may be moving (or both simultaneously). The sensor is commonly

used to measure the speed of a surface, such as the ground.

Using

RADAR technology, this is a non-contact sensor, meaning it measures only the

true relative motion of the target. For vehicle ground speed, wheel slip is

no longer an issue. This sensor can also be used for studying slip angles.

The sensor measures speeds from 1 to 300 MPH and is capable of tracking

object accelerating at several G’s. $2200.

|

|

|

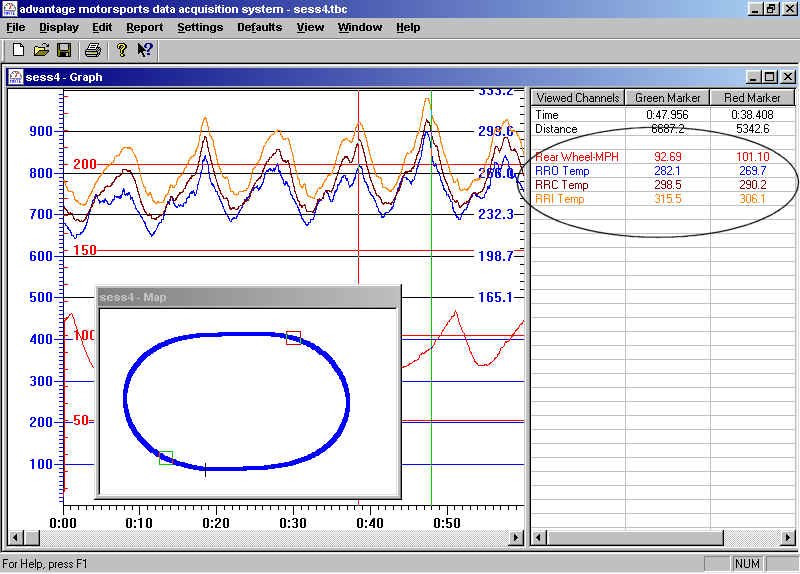

Infra-Red Temperature Sensors: Now you can measure the temperature of components previously not practical with direct contact temperature measurements. The most common application includes brake, engine and tire sensing. Using 3 sensors (inside, center and outside of tire), combined with our data acquisition system and tire temps can be measure ON THE racetrack. The image below shows a graph of Right Rear Tire Temps taken from a Lap of a Late Model Stock Car. Only your imagination is the limitation of what can be measured. Image at Left shows infra red pyrometer probes placed in a customer made bracket to measure 3 tire temperatures at once!

Infra Red Pyrometer Tire Temperature probe with cable and

necessary electronics for data logger interface $ 225 per sensor

|

Infra-Red Temperature

Sensors measuring Tire Temps ON THE Track!

Note: RRO= Right Rear Outer, RRC = Right Rear Center, RRI =

RR Inner

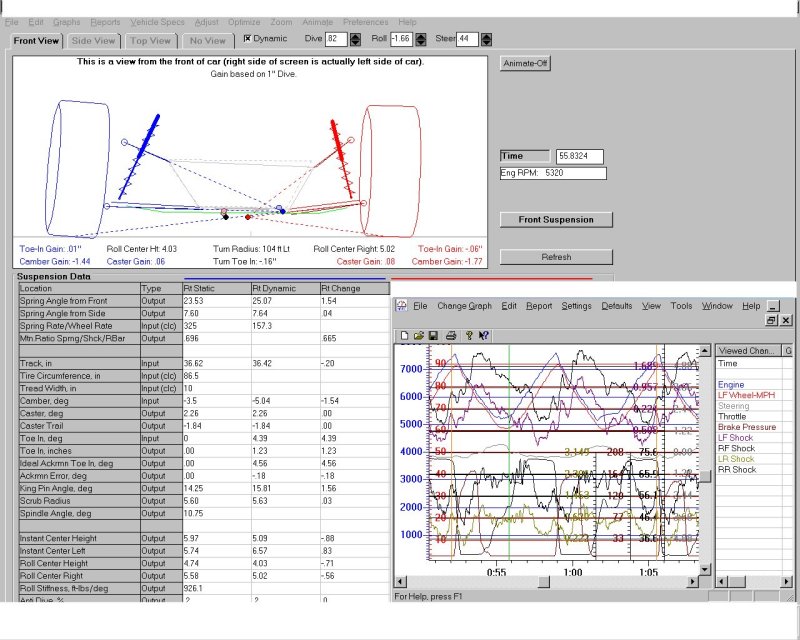

THE ULTIMATE CHASSIS TOOL!

The ULTIMATE CHASSIS TOOL! A 3D Suspension Analysis Program that takes the data

collected ON the RACETRACK and shows you EXACTLY what your suspension was doing!!!

NO ONE COMES CLOSE!!! Not just a simulation program, Not just a graphical interface, but a REAL

HARDCORE suspension program that uses real data from the racetrack. Once you download the data from our Data Logger, you can take that data and run the Suspension/Shock Information directly into our 3D suspension design program. The data can be analyzed in "MOVIE" mode showing changes in the suspension around the track, or point by point analysis can be made of the smallest sample of data!

This 3-D Suspension Analyzer does a complete double A-Arm (wishbone) suspension analysis, including bump steer, Ackerman, caster gain, anti-dive, tire scrub, camber gain and much more. Complete graphs and reports are included, and several new features not found in other programs: $399

Note: While we do not recommend this 3D suspension program for the typical user, it is important to see just how far you can go with our data acquisition systems. As you grow, our systems stay with you!!

REAL TIME RACE TELEMETRY OPTION!

Can't wait to download? Does yoru crew need to see your racing data while the car in ON THE RACETRACK!

REAL TIME Racing TELEMETRY!!! Our radio telemetry

system option will also allow you to view the data REAL TIME while you are on the track!!!

|

![]()